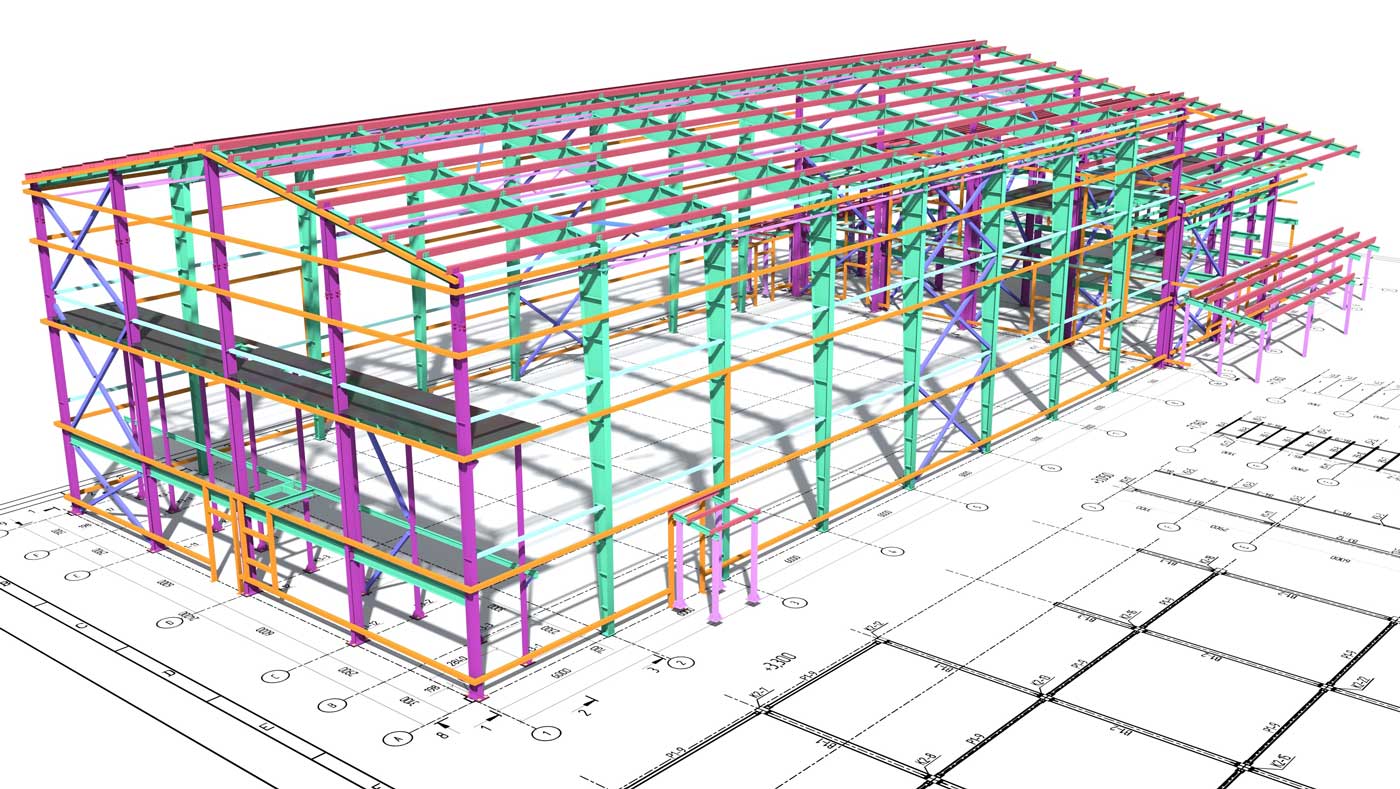

1. Design

The design is an critical step for a good execution of the production. Soanseng workshops cooperate closely with its customers, architects and engineers to develop design solutions that optimize the use of raw materials, production times and therefore the finished structure.